Sustainability & Responsibility

Sustainability & Responsibility

-

Why Sustainable Lighting Matters

Lighting runs for thousands of hours every year. Choosing efficient, long-life LED systems reduces energy bills, maintenance visits and waste – not only for one project, but for every site you support.

- Lower energy use over the full lifetime

- Fewer replacements and service visits

- Less packaging and transport per lumen delivered

-

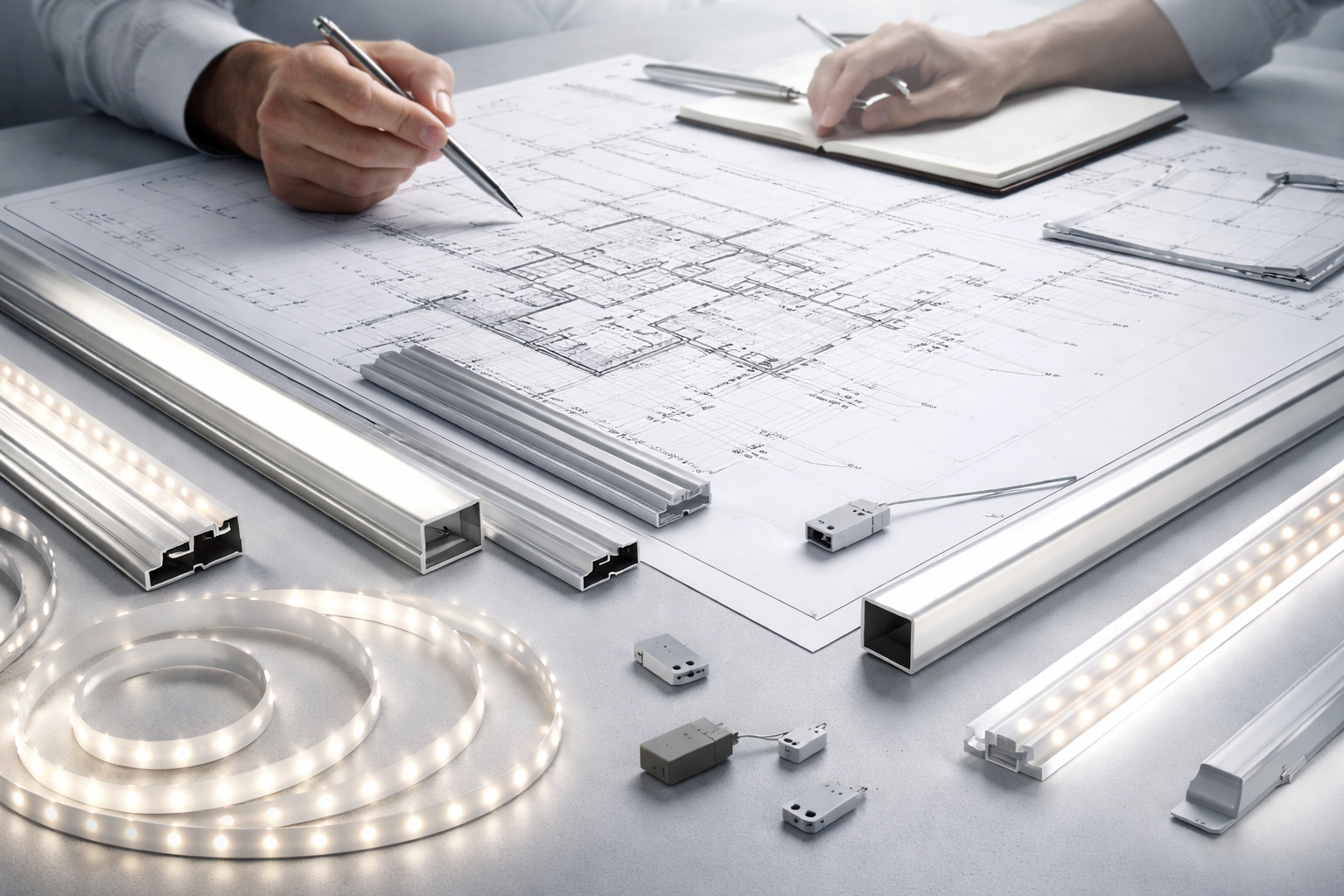

Designed to Last, Not to Be Replaced

- High efficiency LEDs – We continuously optimise lumen per watt, so projects achieve the same light levels with less power.

- Long service life – Proper thermal design, derating and aging tests help our strips, neon and luminaires run stably for years.

- Repair-friendly thinking – Wherever possible we favour modular designs, standard connectors and clear wiring diagrams, so installers can replace sections instead of full systems.

-

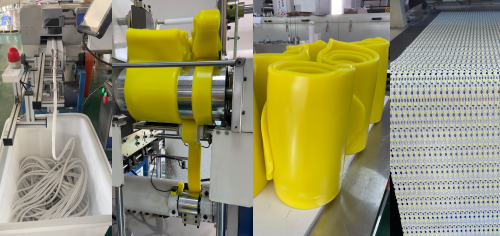

Responsible Manufacturing & People

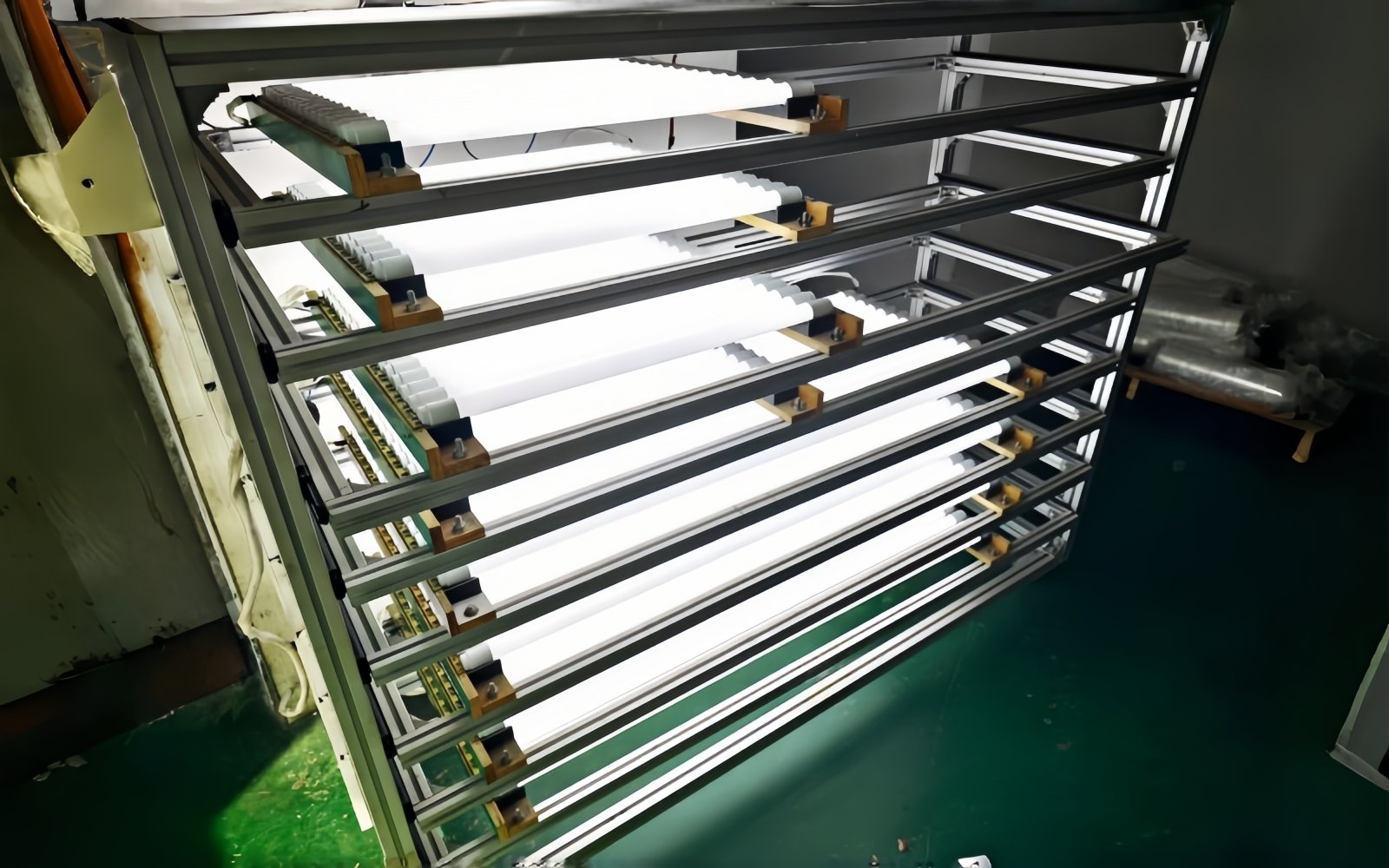

Our factories for COB, SMD, tubes, neon and power supplies are organised for repeatable, stable production rather than “one-off runs”.

- Process control and yield monitoring reduce scrap and rework.

- Aging lines and photometric tests help catch issues before shipping.

- Workspace safety, training and protective equipment support the people behind every reel of LED.

Details of management systems and certifications can be found on our Quality & Certificates page.

-

Smarter Packaging & Transport

- Right-sized cartons – We design inner bags and master cartons to protect products while avoiding unnecessary empty space and material.

- Recyclable focus – Wherever possible we choose paper-based and easily recyclable materials, and label cartons clearly for local recycling schemes.

- Logistics efficiency – Strip and neon systems are packed for high container loading rates, reducing CO₂ per delivered metre of light.

-

Thinking Beyond the First Installation

Sustainable lighting does not end when the product is installed. We design labels, documentation and packaging to make it easier to:

- identify products years later for maintenance or retrofit,

- separate electronics and packaging at end-of-life,

- send products into the correct recycling or take-back streams in Europe and other regions.

-

Sustainability & Responsibility

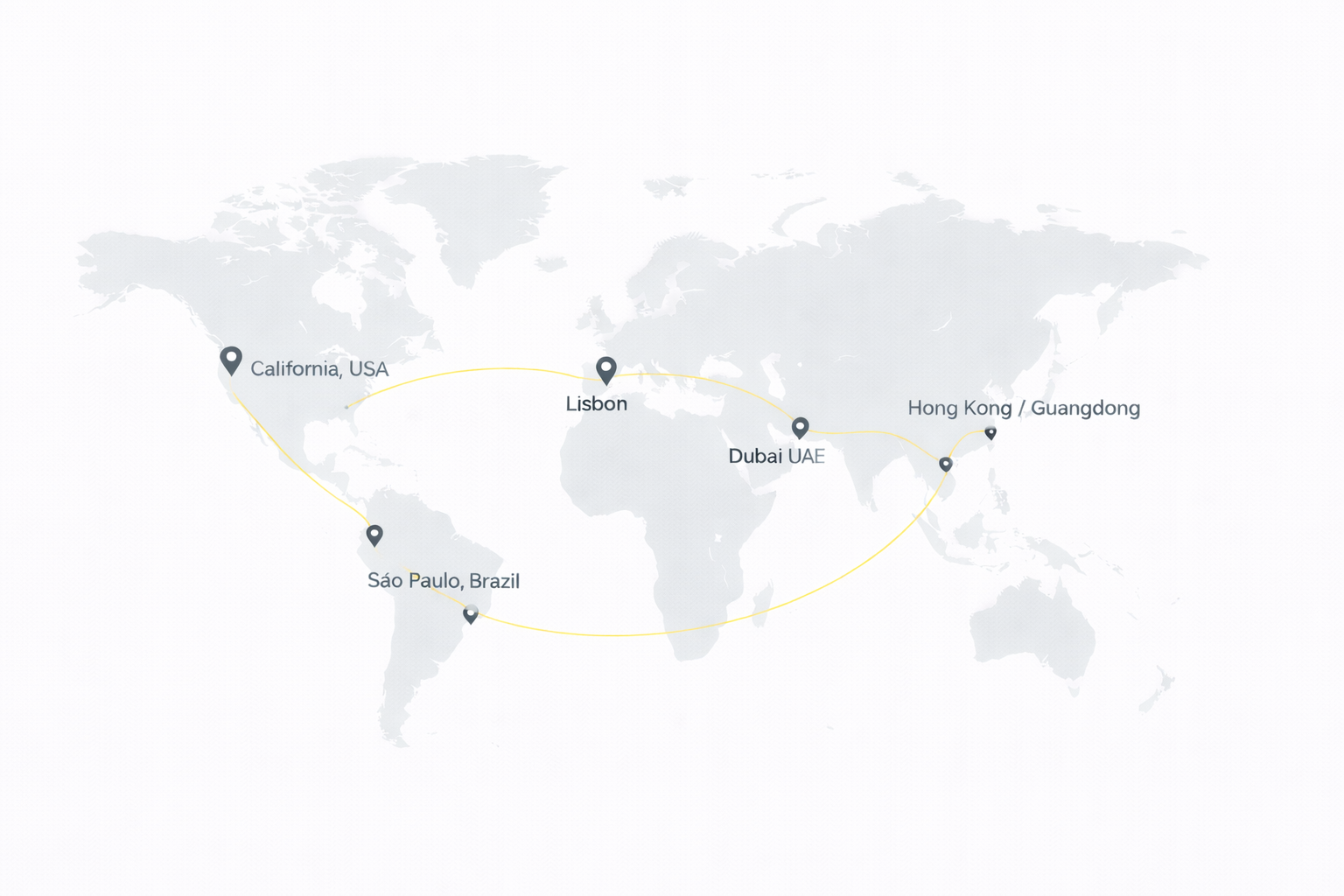

Better light, less impact. At LUMSET® we design LED systems, factories and packaging around one idea: use resources wisely and make products that last.

Our Commitments in Numbers

- 120,000 pcs / month – LED strip & neon capacity organised for consistent quality.

- >50,000 h – Typical rated lifetime for our main LED ranges (under standard conditions).

- 1 partner – One integrated team for products, projects and documentation. Work with a partner who treats sustainability as part of the product – not as a slogan.

Read more …Sustainability & Responsibility

- Hits: 189